Thermocouples & Sensors

A thermocouple is an electrical device consisting of two different conductors forming electrical junctions at differingtemperatures. A thermocouple produces a temperature-dependent voltage as a result of the thermoelectric effect, and this voltage can be interpreted to measure temperature. Thermocouples are a widely used type of temperature sensor.

Commercial thermocouples are inexpensive, interchangeable, are supplied with standard connectors, and can measure a wide range of temperatures. In contrast to most other methods of temperature measurement, thermocouples are self powered and require no external form of excitation. The main limitation with thermocouples is accuracy; system errors of less than one degree Celsius (°C) can be difficult to achieve. Thermocouples are widely used in science and industry; applications include temperature measurement for kilns, gas turbineexhaust, diesel engines, and other industrial processes. Thermocouples are also used in homes, offices and businesses as the temperature sensors in thermostats, and also as flame sensors in safety devices for gas-powered major appliances.

- Nickel - alloy thermocouples

- Type E

- Type J

- Type K

- Type M

- Type N

- Type T

- Platinum/rhodium - alloy thermocouples

- Type B

- Type R

- Type S

- Tungsten/rhenium - alloy thermocouples

- Type C

- Type D

- Type G

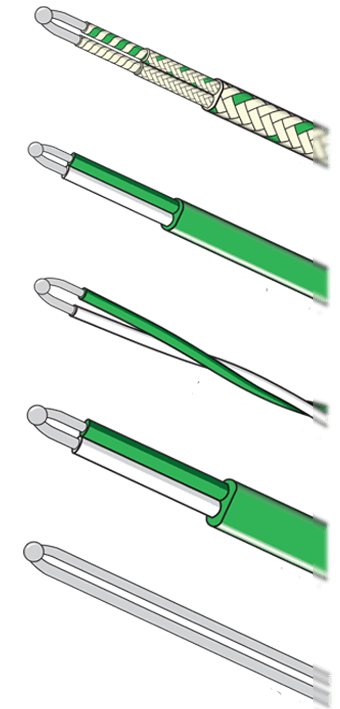

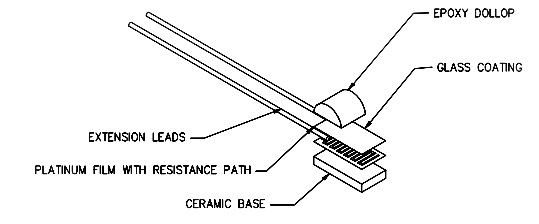

R esistance thermometers, also called resistance temperature detectors (RTDs), are sensors used to measure temperature. Many RTD elements consist of a length of fine wire wrapped around a ceramic or glass core but other constructions are also used.

The RTD wire is a pure material, typically platinum, nickel, or copper. The material has an accurate resistance/temperature relationship which is used to provide an indication of temperature. As RTD elements are fragile, they are often housed in protective probes. RTDs, which have higher accuracy and repeatability, are slowly replacing thermocouples in industrial applications below 600 °C.

Thermometer And Thermostats

A

thermostat is a component of which senses the temperature of a system so that the system’s temperature is maintained near a desired setpoint. The thermostat does this by switching heating or cooling devices on or off, or regulating the flow of a heat transfer fluid as needed, to maintain the correct temperature. Thermostats are used in any device or system that heats or cools to a setpoint temperature, examples include building heating, central heating, air conditioner, HVAC system, as well as kitchen equipment including ovens and refrigerators and medical and scientific incubators.

A thermostat is often the main control unit for a heating or cooling system, through setting the target temperature. Thermostats can be constructed in many ways and may use a variety of sensors to measure the temperature, commonly a thermistor orbimetallic strip. The output of the sensor then controls the heating or cooling apparatus. A thermostat is most often an instance of a “bang-bang controller” as the heating or cooling equipment interface is not typically controlled in a proportional manner to the difference between actual temperature and the temperature setpoint. Instead, the heating or cooling equipment runs at full capacity until the set temperature is reached, then shuts off. Increasing the difference between the thermostat setting and the desired temperature therefore does not shorten the time to achieve the desired temperature. A thermostat may have a maximum switching frequency, or switch heating and cooling equipment on and off at temperatures either side of the setpoint. This reduces the risk of equipment damage from frequent switching.